With Students Away, SMU Innovation Gym Manufactures Face Shields

Usually, the Deason Innovation Gym in the Lyle School of Engineering at SMU is full of students working on projects using 3D printers, laser cutters, and other tools.

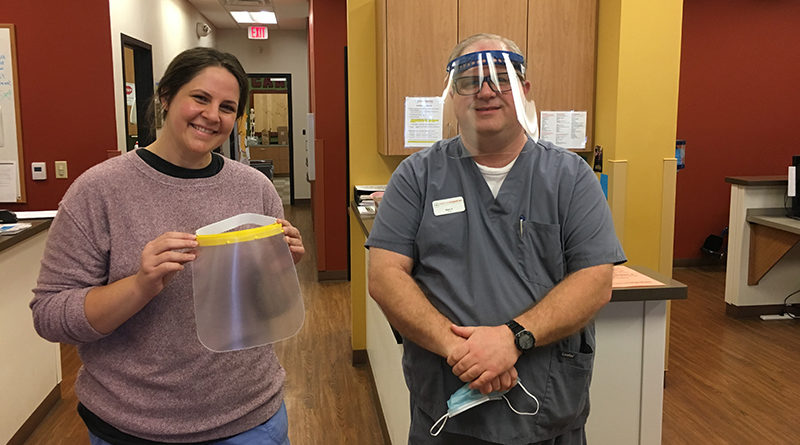

However, with students off campus and learning virtually to prevent the spread of COVID-19, DIG director Seth Orsborn and lab manager Alyssa Phillips are using those resources to make protective face shields for medical workers.

“It’s not only a prediction for Dallas, but they currently don’t have enough healthcare PPE (personal protective equipment) in places like New York and LA, let alone the rest of the world,” Orsborn said. “So to be sort of proactive for Dallas, we’re creating PPE that we can do.”

Medical workers often wear a transparent shield so that no droplets get on their faces while interacting with patients who may or may not be infected, Orsborn said.

At DIG, he and Phillips are using 3D printers to build the ‘halos’ that go around the wearer’s head, using sewing elastic to hold the ‘halos’ in place, cutting the transparent shield material to size with a laser cutter, and assembling the finished products. The face shields then go in bags to be delivered in batches.

Production occurs at about 100 face shields per week and will continue until they are no longer needed, Orsborn said.

“My thought was, hey, our space is open. We have the tools that are needed to make these types of products; let’s just do it.” -Seth Orsborn

A post on SMU’s website says news of the efforts inspired donations from corporations to support the manufacturing process.

“UT Southwestern is asking for batches of 100, and we’re going to other clinics like Watermark Urgent Care…and dropping off batches of 10,” Orsborn said. “The nice thing with delivering (to UT Southwestern) is then they can distribute out, so we don’t have to worry about doing distribution.”

The idea for the project came while watching reports about the plight of healthcare workers fighting the pandemic in Europe and Asia in March.

“I saw that there was already being an issue with not enough PPE in Europe, in Asia, and recognized that that was going to hit us pretty quickly,” Orsborn said. “My thought was, hey, our space is open. We have the tools that are needed to make these types of products; let’s just do it.”

More Online: Seth Orsborn, with the Deason Innovation Gym, is encouraging small clinics and medical practices to get in touch if they need face shields. Visit www.thedig.org

For nearly 40 years, People Newspapers has worked tirelessly to tell the stories—good, bad, and sublime—of our neighbors in the Park Cities and Preston Hollow. To support our efforts, please contact [email protected] for advertising opportunities. Please also consider sharing this story with your friends and social media followers.

Pingback:ICYMI: What's New and Next in Dallas-Fort Worth Innovation » Dallas Innovates